In brief

Before people invest in a company, work for it, or purchase its products, they are increasingly considering its position on environmental, social and corporate governance (ESG) issues. In addition to societal pressures, US and EU regulators are also more active in mandating ESG changes, particularly related to climate risk.

As such, companies are moving to reduce their carbon emissions, with some stating ambitious goals to be carbon neutral in the next 5 to 10 years — yet these goals can be more theoretical than concrete. Bridging the gap between intention and reality won’t necessarily be easy, but what’s good for business and the planet doesn’t need to be in conflict: optimization and simplification across the supply chain can reduce emissions, and advances in technology are making the economics of renewable energy and electric vehicles much more favorable every year.

“In addition to the traditional pressures of cost reduction, cash extraction and industry 4.0, the multiplicity of demands on chief supply chain officers now includes resiliency and sustainability,” says EY Global Supply Chain Leader Glenn Steinberg. Supply chains are a key area of ESG focus, as they are both a large source of emissions for companies as well as a large percentage of operating costs, and they are also susceptible to the risks inherent in climate change, such as natural disasters and rising temperatures. Today, businesses across sectors are rethinking everything from what materials they use in their packaging to what markets they compete in and where their factories are located.

It makes sense to scrutinize how products are sourced, produced, provided and perhaps even reused in the circular economy. But where should you start?

Chapter 1 The changing landscape

Regulators are putting sustainability higher on the agenda, and consumers, employees and others are making the topic a priority as well.

ESG is not a new topic on C-suite agendas, and the business case for action is well-established. For example, supply chain sourcing and manufacturing has long focused on human rights aspects — such as child labor and working conditions. Some large companies have closely monitored their suppliers for their carbon footprint and sustainability key performance indicators. Forward-thinking retailers have targeted energy savings tied to operating their physical stores to reduce their overall environmental impact, and they have improved transportation routes and leveraged hybrid vehicles for last-mile delivery. Consumer packaged goods companies have focused on reducing their packaging and reducing their water usage. And even health systems are looking to improve energy efficiency of their hospitals and power their generators with on-site solar panels.

Yet regulatory action this year in the US, with new momentum from the Biden Administration, has added greater urgency to the debate, as well as the need to consider ESG more broadly within supply chains. For instance, the SEC hosted a public consultation process on climate-related disclosures, and its spring 2021 rulemaking list includes a proposed rule on climate change disclosure, among other ESG topics. More change is on the horizon in what companies will need to provide not just in their operations but in their supply chains. The Biden administration has also issued executive orders on environmental sustainability and its impact on the economy, most recently to drive more responsibility among financial institutions on climate disclosures and financing. Globally, the US has also rejoined the Paris Agreement on climate change.

Investors and consumers are also compounding the pressure to act. In an EY survey of global institutional investors from 2020, 73% of respondents said they will devote considerable time and attention to evaluating the physical risk implications of climate change when they make asset allocation and selection decisions, and 71% said the same of transitionary risks. Among consumers, 49% say they will prioritize the environment and climate change in how they live and the products they buy, according to the EY Future Consumer Index in March 2021. (And 26% say sustainability will be their most important purchase criteria three years from now.)

Chapter 2 What to do

Plot your net-zero future today by reimagining the life cycles of your products, how they’re provided, and whom you collaborate with.

Companies today have more levers to pull across the value chain, and the key groups are all making decisions that have implications for each other. For instance, one manufacturer sets a goal of having a net-zero fleet by 2025, so they need to engage with the third-party logistics suppliers to support that effort. The pressure to fulfill such an environment mandate then spreads to auto manufacturers, affecting demand — which partly explains why some of them have made pledges to go all electric as soon as 2030. Here’s what we recommend:

Define a path forward — don’t just set a goal

Many companies today are announcing that they’ve set a net-zero target for a certain year, but there may be more hope than concrete specifics behind those proclamations. Renewables offsets and virtual power agreements are useful today, but determining how to effect meaningful emissions reductions should drive your debate from the beginning, and scrutiny of your supply chain is imperative across sourcing, manufacturing and transportation.

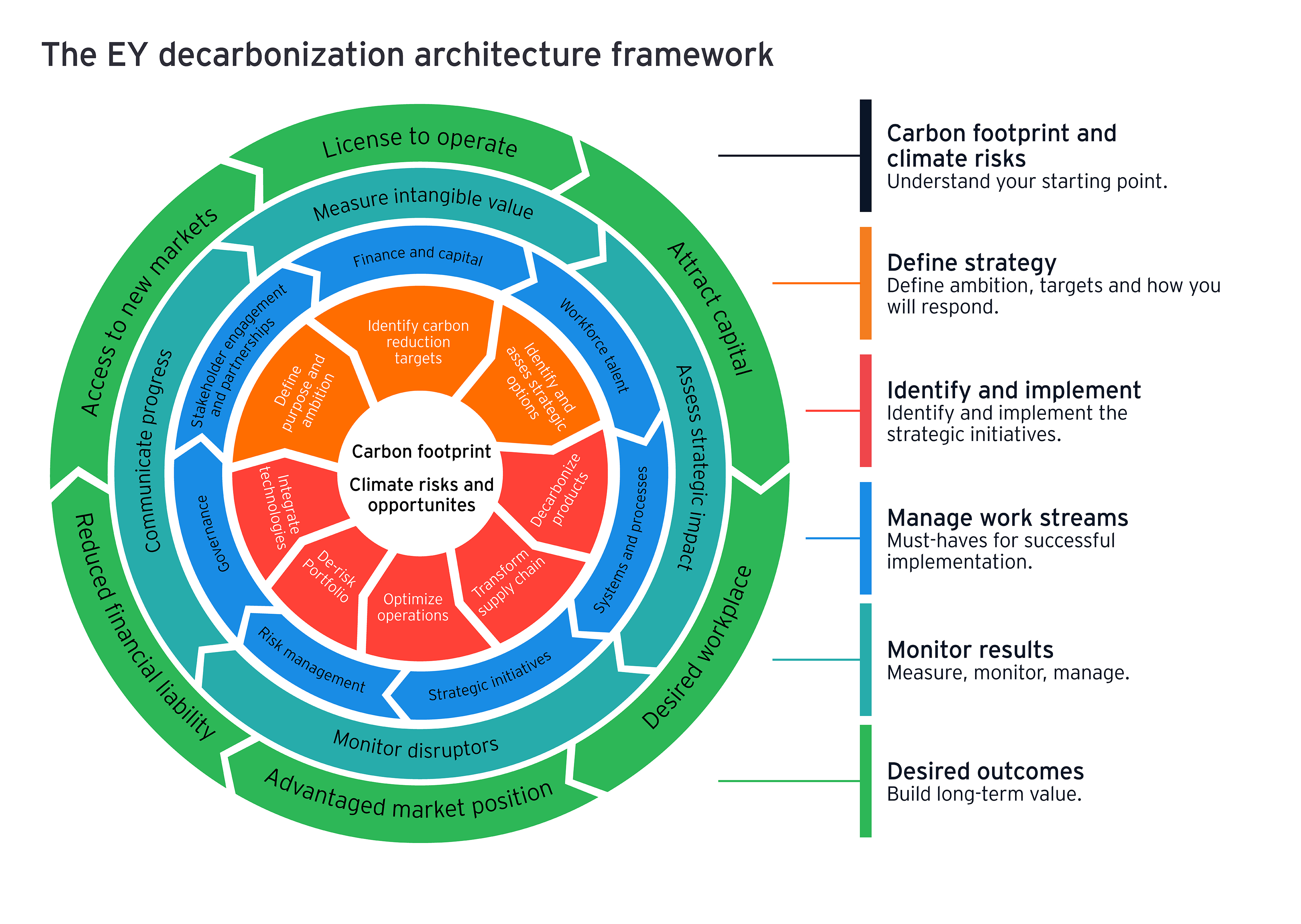

The EY Decarbonization Architecture offers a framework for understanding where to start, what tools are at your disposal, and how to align metrics with outcomes. This is not a reporting framework, although similarities exist when compared with the Task Force on Climate-related Financial Disclosures — instead, it is intended to provide suggested capabilities or competency areas for discussion.

Benchmark and baseline your data

As our framework notes, knowing what your carbon footprint looks like now, and to what extent the supply chain makes up that footprint, is a crucial first step toward defining your road map. You are then equipped to focus on the decarbonization methods and levers best suited for your business, and to think about the metrics to embed to track that activity.

Rethink how you engage with suppliers

When you’re identifying the levers to pull, think about which players are impacting those levers and engage with them — you may be surprised by how much they have in place already amid greater pressure from stakeholders such as investors and consumers, as well as advances in electrification. Collaboration across the value chain is vital for meeting goals and commitments. Companies should feel empowered to demand data-based targets from their suppliers, rather than merely asking them to reduce emissions. Consider adding different criteria to your scorecards for suppliers and third-party logistics providers with those goals in mind.

Scrutinize the full life cycle of your products

You can make a large impact in reducing emissions through innovation up front during product development — for instance, through product and packaging design centered around greater energy efficiency, recycling and more sustainable materials. In sustainable manufacturing, a view of the whole product cycle is crucial for optimizing manufacturing systems, products and services. And even if you don’t use much energy to manufacture a product, perhaps the end consumer will use it in a way that strains environmental resources, creating Scope 3 (indirect) emissions in your sustainability reporting. Through a full-life-cycle view, you can drive positive change through adapting what raw materials you use, which suppliers you rely on, and when and where manufacturing can take place, with the effects of climate change in mind from the beginning.

Focus on logistics

The traditional way toward a more sustainable supply chain has been through procurement. Now you should also be looking at the fulfillment side — for example, to examine ocean freight, to the distribution centers, to last-mile delivery — for more impact, as decarbonization efforts in transportation are picking up momentum. Thanks to cheaper battery technology, the economics of fleet electrification are making more and more sense, and some automakers are moving away from internal combustion engine vehicles altogether. While perhaps considered a niche product for the affluent and environmentally focused today, electric vehicles are expected to achieve cost parity with internal-combustion engine vehicles in about five to six years in most regions, and government incentives (and regulation) are fueling the transition. Separately, implementing a digital twin — a virtual replica of your full supply chain — provides a way for you to experiment virtually with new logistics routes and warehouse picking/truck loading for greater optimization.

Explore the circular economy

Similarly, your products can be designed to have a second life or else be recycled or repurposed after their original use has finished. In the circular economy, disposing is replaced with collecting and reusing, thereby closing the loop of a product life cycle. Currently, the global economy is only 8.6% circular, yet it has the potential to cut emissions by 39%, according to the Circularity Gap Report 2021. Efforts include adopting programs that use incentives to encourage an end-of-life product to be returned to the original manufacturer or designated ecosystem partner, providing the resources needed for new products. Supply chain designs must account for durability and consistency — for instance, to account for how easily components can be dissembled — to keep them in play longer.

Lauren Rogge, Senior Manager, Climate change and sustainability services, Ernst & Young LLP, also contributed to this article.

Summary

Investor, customer and regulator expectations are becoming more focused on sustainability. As companies set carbon-neutral or carbon-negative goals, supply chains are a natural target for reduced emissions, particularly through optimized manufacturing and vehicle electrification in logistics. But the opportunities run deeper for those who scrutinize how their products are made and used — and potentially reused. Planning effectively for tomorrow (or 2035) also means taking steps forward today, and while a net-zero supply chain isn’t easy to achieve, know that smarter use of resources can have a big impact both on your bottom line and the health of the planet.